Large Scale Mining

Free / Large Scale Mining

DNI's Black Shale Metals Projects

October 2012 by Leonard

While much attention in northern Alberta has been focused on the rapidly growing “oil sands,” another story of particular interest to the mining community has been taking shape virtually unnoticed in the same region.

Toronto-based DNI Metals Inc. is working aggressively to advance their polymetallic northern Alberta Black Shale metals projects toward production as rapidly as possible. For sheer size and variety of metals which might be recovered, the company’s SBH Property located 120 Km (75 mi) north of the famed mining center of Fort McMurray, Alberta is of considerable interest. Your columnist was most fortunate to be able to visit the company’s project area in mid-August along with several company executives, including company President and CEO Shahe F. Sabag.

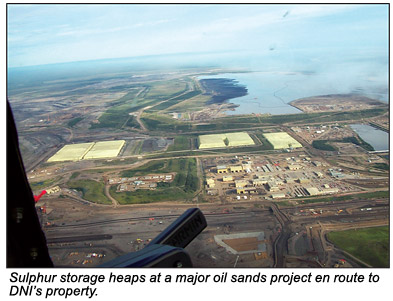

While flying by helicopter from the industrial center of Fort McMurray to the SBH Property, we flew over a range of oil sands recovery projects, many of them enormous in scope. We also noted the presence of large sulfur storage areas at some of these recovery projects, and, as noted below, these materials are planned to become part of DNI’s development strategy.

One of the benefits of being in close proximity to a center of mining activity such as Fort McMurray is the presence of excellent area infrastructure including quality air transportation, mining equipment and experienced  mining personnel.

mining personnel.

The SBH package comprises some 2,720 square kilometers (272,000 hectares), all of which is underlain by black shales that host the metallic values. DNI began assembling the land package in 2007, and then expanded it in 2008 and 2009. The entire property is underlain by the targeted black shales, which are part of the flat-lying layer-cake arrangement of sedimentary formations of the Western Canada Sedimentary Basin.

The area was intensely explored in the 1990s by third-parties and it was during this process that the metallic potential was also discovered. However, the metals could not be extracted from the black shale with available processes at the time and the projects were terminated. This changed in 2005, when extraction of metals from black shale was made possible by relying on bioleaching. Among the metals discovered contained within the black shale are molybdenum, nickel, uranium, vanadium, zinc, copper, cobalt, silver, gold, lithium, specialty metals (like scantium and thorium) and rare earth elements (REEs).

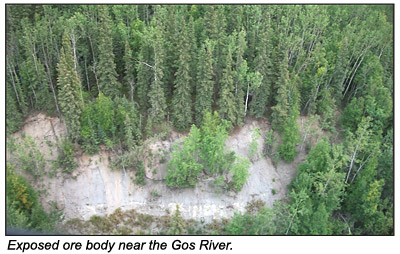

DNI’s primary focus is on two flat-lying, near-surface black shale formations that are beneath the surface across all of DNI’s property and which carry elevated organic carbon in addition to base metals, uranium, specialty metals and REEs. These are the “Second White Speckled Shale” and “Shaftesbury Formation.” Both formations outcrop in river valleys across the eastern parts of the property, but other areas are covered by up to 150 meters of overburden. During our visit, we observed that these materials are frequently coral in color and are relatively soft and easily handled; concepts that should aid in future recovery development.

At one time, the overburden materials, consisting mostly of Labiche formation shale, were considered to be waste material that represented a net cost for removal, but company geologists have suggested that the overburden itself may actually represent a recoverable resource in the form of a third formation and a resource study is now underway to prove up this concept. Results of the study are expected to be released shortly.

DNI’s primary target is the Second White Speckled Shale Formation since it is exposed on surface or is under thin overburden cover and is, as such, amenable to mining by open pit. In all, there are six areas of interest on DNI’s property, two of which have been drill-tested and identified as large mineralized zones named “Buckton” and “Asphalt” and four other target areas which have been entitled “Buckton South,” “Eaglenest,” “McIvor West” and “North Lily.”

“Buckton” is a mineralized zone of 26 sq. km with potential to contain 1.4 to 1.5 billion short tons of which 250 million short tons—extending over a 5.7 sq km portion of the zone —has been drill-tested, and has been classified as an initial “Inferred” Resource. The mineralized portion is approximately 21 meters thick, is partly exposed and is open in three directions. “Asphalt” is a mineralized zone of 4.5 sq. km with potential to contain 125-151 million short tons in an 11-meters-thick zone that is also open in three directions.

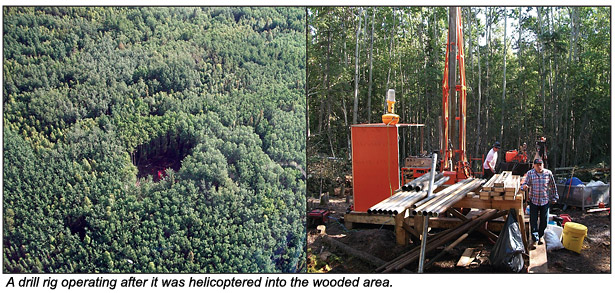

DNI recently resumed in-fill and exploratory drilling at its black shale projects. Three programs are planned with the goals of expanding and upgrading the existing Buckton initial Inferred Resource. Drill testing the Buckton South target will determine whether it is an extension of the Buckton Zone 9 km to the south or a separate mineralized zone, and DNI is exploring for possible northerly extensions of the Buckton Zone over at least an additional 6 km of strike.

Due to heavy forest cover and a present lack of roads into some target regions, transportation of the drills is accomplished by helicopter, a method requiring a high degree of skill and diligence.

Considerable attention has been devoted by DNI to determining the most advantageous method of recovering metals from black shale and one technique that has returned very favorable results is “bioleaching,” a metals  extracting process now in operation at the Talvivaara Mine in Finland. The Talvivaara mining operations extract multi-metals from mineralized black shale relying on heap leaching using naturally occurring bacteria that feed on minerals to release the metallic values.

extracting process now in operation at the Talvivaara Mine in Finland. The Talvivaara mining operations extract multi-metals from mineralized black shale relying on heap leaching using naturally occurring bacteria that feed on minerals to release the metallic values.

In relation to the DNI projects, bioleaching would involve the release of microbes already found in the black shales of Alberta and, when released on ground rock and fed with sulfur and water, they reproduce as micro-organisms do, creating heat in the process. This produces acidic secretions that dissolve the rock, and sulfur can be used as an agglomeration material to aid in the process. Mineral values are subsequently recovered from these secretions. While the process may be somewhat slower than conventional recovery methods, it is environmentally friendly (such as using up above-ground sulfur stocks) by using no polluting chemicals and little to no outside sources of energy.

It should also be noted that in order for the process to become economically effective, President Sabag noted, “You have to shift a lot of rock. If you don’t bulk mine, you don’t make money.”

DNI completed the resource study on the Buckton Cover Rocks and plans to shortly advance the Buckton Zone toward a Preliminary Economic assessment (Scoping Study) once the Buckton Inferred Resources have been revised with current drill program information.

DNI has also teamed up with CANMET Mining and Minerals Science Laboratories in order to collaborate on conducting test work toward the commercialization of their black shale heap leaching process.

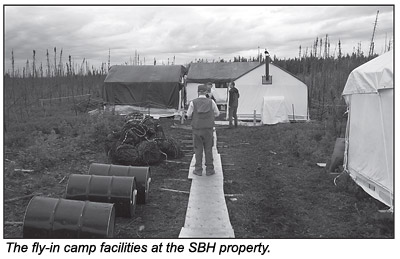

The company has established a fully-equipped camp, presently accessible by helicopter. The camp includes housing areas, kitchen and dining facilities, equipment storage facilities and geologic staff working areas. The camp is located on high ground which allows for fine views that are not only scenic, but also show the uplifted areas where the resources are located some 300-400 meters above the surrounding terrain.

Obtaining power sources for continuing development is an important economic consideration as diesel fuel generation can be excessively expensive when power demands are substantial. During our discussions with President Sabag, he offered two concepts, one of which was tying into the Alberta power grid while the other  was somewhat unique. As part of our project air tour, we flew along a rather small stream called the “Gos River” in an area of the property known as “GOS1.” Sabag told us he had conducted preliminary research into creating a run-of-river power generating facility. Even though the area receives only moderate annual precipitation, the steepness of the river’s flow could make it amenable to the construction of hydroelectric facilities. Should this method prove effective, once the facilities were in place, any power generated would be virtually free. Studies relating to that idea are continuing.

was somewhat unique. As part of our project air tour, we flew along a rather small stream called the “Gos River” in an area of the property known as “GOS1.” Sabag told us he had conducted preliminary research into creating a run-of-river power generating facility. Even though the area receives only moderate annual precipitation, the steepness of the river’s flow could make it amenable to the construction of hydroelectric facilities. Should this method prove effective, once the facilities were in place, any power generated would be virtually free. Studies relating to that idea are continuing.

Company plans going forward include hiring the consulting firm of P & E Mining Consultants to complete a Scoping Study by the end of 2012; completing a Resource Estimate revision to include the results of the 2012 drill programs; and analyzing the results of the 2012 drill programs to establish future exploration and development targets.

Sabag noted that the areas under DNI’s control are known to contain sizeable resources of the metals noted earlier and he offered examples to illustrate their scope including 338 million pounds of molybdenum; 34 million ounces of silver; and just under one billion pounds of zinc. He also stressed some important considerations relating to the SBH Property.

First, it is located in the Province of Alberta, which has a history of strong support for all forms of resource development and which is consistently ranked high in the Fraser Institute rankings of mining jurisdictions. Also, Alberta is located within Canada, a country known for political stability, an important consideration for product end-users who do not wish to encounter some of the risks inherent in relying on supplies from less stable countries. In addition, by using the process of bioleaching rather than the more traditional caustic leaching or smelting involved in most open pit mining operations, the entire regulatory and permitting outlook becomes more favorable. Since the region has come under recent close environmental scrutiny thanks to their ongoing enormous oil sands recovery operations, this last consideration could prove to be important.

DNI’s management team is led by President and CEO Sabag; Chairman Denis A. Clement; CFO Colin A. Grant and Directors Michael E. Butler, Raymond Mitchell and Nicholas Tintor. The technical team is led by Sabag and a select group of outside experts.

_______________

Further is available by email at info@dnimetals.com or on the Internet at www.dnimetals.com.

© ICMJ's Prospecting and Mining Journal, CMJ Inc.