Prospecting & Detecting

Free / Prospecting & Detecting

Detectors: Past, Present and Future

June 2016 by Steve

I consider myself fortunate to have seen nearly the entire consumer portion of the metal detector industry occur in my lifetime. Detectors were invented long before I was born, but it was in the 1960s when they started to become an item popular enough to power a fledgling industry. The key development was miniature transistor technology replacing the old fashioned tube technology of the 1950s, making lightweight, affordable detectors possible.

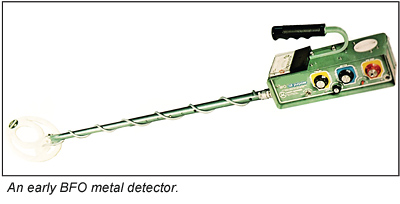

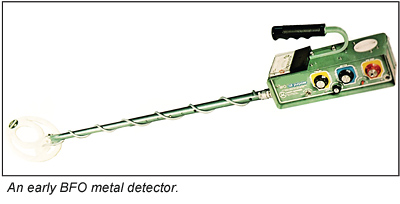

The first popular metal detectors were simple machines relying on a principal called Beat Frequency Oscillation, which was quickly shortened to BFO. These detectors feature a distinct “putt-putt-putt” sound that the operator listens to while operating the detector. Tuning amounted to holding the coil at a precise height over the ground and setting the machine to produce a very slow series of these sounds.

The BFO is an incredibly simple machine that can be easily built at home with a few components and some wire. The first commercial units were little more than homemade units sold to the public. Metal detectors are electromagnetic devices, and as such, the BFO detector could detect items that were conductive or magnetic—or both together.

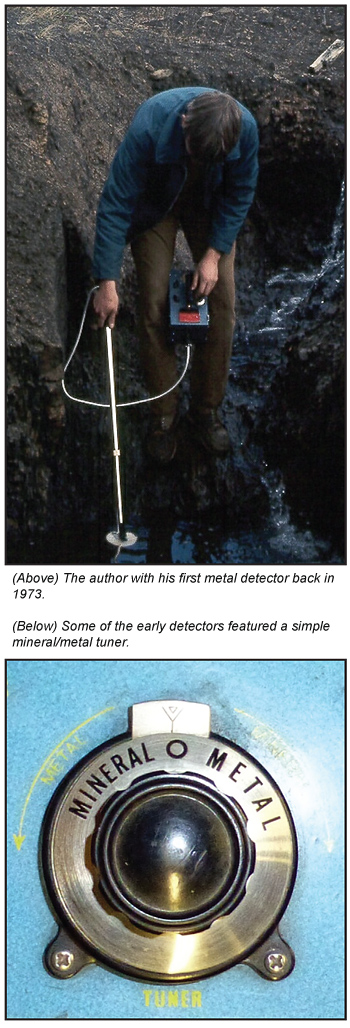

Unfortunately, common ground minerals have magnetic properties. Magnetite is extremely common in most soils and is easily attracted to a magnet. Even small amounts of it in soils will produce a signal on a metal detector, as will some other iron minerals such as maghemite. BFO detectors had no way to compensate for or tune out this mineral effect. However, it was simple to design these machines so that mineral effects produced signals directly opposite to those produced by conductive items. BFO detectors were often referred to as “metal/mineral detectors” and the controls were set up such that the operator could search for one or the other.

Almost all BFO detectors had a tuning control that governed the mineral effect by turning the control one way, and the conductive effect by turning the control the opposite direction. The control nulled midway. If tuned to the conductive side of things, a conductive item would cause an increase in the rate of the “putt-putt” sound while exposure to magnetic minerals would cause a decrease in the rate of the signal sound.

The main problem was the ground itself. If the detector coil was tuned at precisely 2” over ground containing magnetite, lowering the coil to the ground would cause the slow putt-putt sound to decrease or even cease altogether as the coil got closer to the minerals. Conversely, raising the coil would cause an increase in the putt-putt sound, just like that heard when the coil went over a conductive item. Again, conductive items cause an increase in the signal sound and minerals a decrease in that sound. In theory and in practice, an exact amount of mineral material would exactly offset and cancel the signal from a conductive item. Minerals were producing a negative signal and conductive items a positive signal.

Therefore, not only could the ground minerals cancel a conductive target, but the ground could produce false positive signals by simply raising the coil off the ground or by passing over a depression in the ground. Some operators used this sensitivity to surface mineralization to seek out and find surface concentrations of black sands as an aid in prospecting. For most purposes, such as common coin detecting, it was a constant issue trying to keep the detector both properly tuned and at an exact distance over the ground.

One nice side effect with these early BFO models was that magnetic metals such as iron and steel were seen as essentially no different than magnetic ground minerals and so produced a negative ground type signal instead of a positive conductive type signal. The BFO detector came with its own built-in ability to ignore most manmade ferrous items.

In the 1960s, most places had never seen a metal detector, so even these early BFO machines with their ability to find a coin at only a few inches produced amazing results. There were decades of silver coins literally blanketing parks and school yards of the day. Treasure hunting magazines started appearing in the 1960s and the covers had photos of people with amazing piles of silver coins and other items found with the early machines.

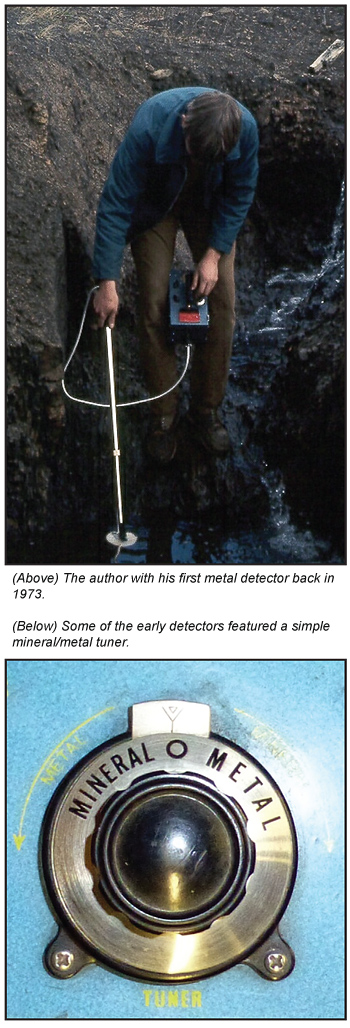

When I started shopping for my first metal detector in the early ‘70s, another technology was hitting the scene. BFO detectors had a single coil of wire that did the job of creating the electromagnetic field and sensing detectable items. The new machines featured a transmitter coil and a receiver coil working together in an electronically balanced fashion to find detectable items. These were referred to as Transmitter/Receiver or simply T/R detectors.

My first big detector decision was whether to buy a BFO or the newer T/R type detector. BFO was the tried and proven technology, but T/R was that new, latest and greatest thing. There really was no strong reason to buy one over the other at the time as one detected items about as well as the other. I did finally opt to go with that newer technology though, and in 1972 bought my first detector, what at that time was a top of the line T/R model.

My first T/R detector operated almost exactly like a BFO detector. It had a mineral/metal tuning control where ground minerals and manmade ferrous metal reacted on one end of the control, and conductive metals on the other end of the control, with a null in the middle. The machine had to be tuned at an exact distance over the ground. Lowering the coil detuned the machine and raising it produced a false positive signal.

The only real difference with the T/R was that instead of a slow “putt-putt” sound that increased in rate near metal, a quiet sound was produced that got louder in volume. It was somewhat similar to modern detectors except that no motion was required to get a signal. In other words, you did not need to wave the coil over the item to get a signal—simply holding the coil over a coin would produce a loud sound for as long as the coil was held steady over the target. Move away, and the signal went away. This made pinpointing a snap. Just like a BFO detector, these early T/R detectors ignored nails and common ferrous trash as being a ground signal. Aluminum was not yet a common trash item so remarkable results could be obtained. I found more silver coins with my early machines than I have since with far better machines just because the silver was there to find.

It was not long, however, before a couple real advantages were found with the two coil transmitter/receiver design. First, there is a delay between the transmitted signal and the received signal that can be measured, referred to as “phase shift.” This can be used to determine information about the item being detected and whether it is ground mineral signal or conductive signals. It can even be used to determine the relative conductivity of various targets.

Rapid advances came in the next ten years. The most important was the ability to determine and largely eliminate the ground signal. This resulted in almost immediate doubling and tripling of detection depths compared to units that lacked the ground canceling capability. It also made detectors much easier to operate by eliminating the retuning and false signals that early machines produced by simply raising or lowering the coil over the ground.

It just so happened that these ground canceling detectors ran at Very Low operating Frequencies and so were soon referred to as VLF detectors; the term rapidly becoming synonymous with “ground canceling detector.” These deep-seeking machines lacked any discrimination capability and, in fact, because of the way they worked, nails and other man-made ferrous trash suddenly got treated just like other conductive targets. The ground was canceled out, but not the nails and other ferrous items. This led to dual circuit VLF/TR detectors, where the VLF circuit was the deep-seeking, non-discriminating circuit. When a target was located, the operator could switch to the T/R circuit to help eliminate ferrous trash like nails and bottle caps. The problem was the T/R circuit still only worked on items a few inches deep, so deep nails and other junk were a big problem.

This was an incredibly important development. The real problem in metal detecting is not so much in detecting items, but in eliminating items you do not want to detect. The ground is by far the main detectable item that needs to be eliminated and it is improvements in ground canceling technology that have done more than anything else to advance metal detecting technology. It was VLF ground canceling capability that finally opened the door to using metal detectors as useful prospecting devices. The intense ground mineralization associated with gold, in particular, made the earlier machines ineffective for that purpose. Pictures of gold nugget finds began showing up in magazines.

Shortly after ground canceling VLF detectors became common, phase shift was used to create discrimination circuits that could eliminate items based on their relative conductivity and size. Better yet, this additional application of phase shift technology operated to nearly the full detecting depth of the machines unlike the simple T/R discrimination circuits available at the time. In addition, it was possible to indicate via a meter what the relative size and conductivity of the item was. This, in turn, could be calibrated to indicate where exactly certain man-made items like coins fell on the meter since all dimes read nearly the same every time.

Early discrimination systems had lots of issues, like the need to be swept over the ground at speeds not much different than swinging a golf club. But improvements came fast and the VLF/TR detectors were soon replaced in the 1980s by machines very similar to what we use today.

A variation in the basic technology also occurred in the late 1980s when it was found that detectors running at higher frequencies worked better for gold prospecting. Most coin type detectors of the day were running in the 3 kilohertz (kHz) to 8 kHz range. Machines designed strictly for gold prospecting appeared running at 19 kHz and later at 50 kHz and even 71 kHz. These detectors featured exceptional ground handling capability but mainly an ability to find much smaller, low conductive targets than would be the norm with the machines running at lower frequencies.

One last twist in VLF detectors came along in the form of machines that receive and compare more than one frequency at a time. These multi-frequency machines use this comparison to achieve better ground balance and target ID accuracy.

The 1990s saw the advent of pulse induction (PI) detectors from many manufacturers sold for the purpose of underwater detecting. Unlike VLF detectors, which constantly transmit and receive at the same time (continuous wave), pulse induction machines alternate between transmitting and receiving. They work by inducing a very short-lived current into conductive items called an “eddy current.” These eddy currents last for micro seconds after the transmitter shuts off, and are in turn sensed by the detector when it goes into receive mode. The better the conductive properties of the target, the longer the eddy currents last. This allows the PI detector to completely ignore targets that no longer have eddy currents depending on how long the delay is between the transmit and receive mode. The longer time an eddy current lasts, the more detectable the target, and as a result pulse induction machines are referred to as operating in the “time” domain. This would be as opposed to VLF or continuous wave detectors, which operate in the “frequency” domain.

The ground signal in most instances can be automatically ignored with a PI detector, and in the case of salt water, the false signals resulting from conductive salt water can also be ignored. Basic PI circuits are very simple and so this made them a good choice for waterproof detectors. However, simple PI detectors have no discrimination—they detect all metals. This limited their use for normal detecting tasks. And although they ignore normal ground they still have issues with extreme mineralization and mineralized rocks.

The next breakthrough in detecting came with the invention of ground balancing capability for pulse induction detectors. Adding ground canceling capability on top of the already inherent PI’s ability to ignore most ground created machines far more able to handle bad ground conditions than was possible with continuous wave technologies of the time. However, phase shift being a function of the continuous wave technology saw high power pulse induction machines relegated to types of detecting where discrimination was less important than sheer power. The ground balancing pulse induction (GBPI) detector revolutionized gold prospecting.

Which brings us almost to the present day. Most choices these days still boil down to various continuous wave detectors running at one or more frequencies, plus PI detectors that either have the ability to ground balance or do not. Pulse induction detectors rule the day for ground canceling capability and sheer depth. Continuous wave detectors (still commonly called VLF detectors) offer much better discrimination capability plus have an edge for detecting the smallest and less conductive targets that PI detectors may struggle with or miss entirely.

The so-called Holy Grail of metal detecting has been a detector that offers all the power of a PI time domain detector combined with the target discrimination capability of a continuous wave frequency domain detector. Part of that dream was realized in the last two years by the release of a detector that is a constant current (continuous wave) detector but that employs sophisticated time domain techniques to act very much like a pulse induction detector. Or perhaps more accurately very much like a super VLF detector. This machine combines most of the ground canceling capability of a PI detector with the ability to detect low conductive items missed by most PI detectors. Unfortunately, the ability to discriminate targets is still lacking. However, the fact that it is a continuous wave detector means that phase shift information is available to the unit for discrimination purposes. I have no doubt such capability is being explored in the lab at this writing.

While this may seem like pure speculation on my part, there are two recent patents that help offer clarity to this situation. First is patent US 8878515 B1, which describes a Constant Current Metal Detector. The summary of the invention:

“The new invention provides better target object characterization and identification while eliminating ground mineralization detection.

“A constant current in the energizing coil establishes a constant magnetic field that goes from zero to a strong, but constant, field very rapidly, as in less than 10 microseconds. Target objects such as coins and other eddy current objects have an energizing time constant usually exceeding 10 microseconds, wherein the eddy currents accelerate until field equilibrium is reached in the target object.

“A constant current or constant magnetic field does not produce a significant signal in a receive coil after the transition from zero to constant current from ground mineralization permeability (powdered iron or ferrite equivalent). Target object eddy currents do produce a signal of varying amplitude throughout the constant current period, depending upon eddy current charging time or inductance of the object, usually not a simple exponential due to configuration of the target object. i.e., diameter, thickness, conductivity, etc.”

Next we have patent US 8629677 B2, which describes a Hybrid Induction Balance/Pulse Induction Metal Detector. The abstract and summary of the invention:

“A new hybrid metal detector combines induction balance and pulse induction technologies. Target signals are generated from a transmitted wave that has both induction balance and pulse current inducing characteristics and uses pertinent sampling of the receive data. Combining the two data sources provides eddy current target identification while excluding ground permeability and remanence obscuration.

“The new metal detector combines both induction balance and pulse technology. The methodology uses a truncated half sine of exciting current to the energizing coil and an induction balanced receive coil. The half sine is created by a charged capacitor being switched on to the energizing inductor coil and then being switched off before the end of a half cycle of resonance.”

These are not just obscure patents from somebody you never heard of, but from well known, major manufacturers. The potential of the existing new technology on the market and these patents cannot be overstated. It appears the long desired combination of pulse induction depths with VLF style discrimination capability is near at hand.

What does this mean for the prospector who employs metal detectors? Some of the best opportunities that still exist for finding gold in particular are in the heart of well known gold locations. However, these locations are often buried in literally tons of junk. There was no garbage service at the old mines, and every metal item transported to the old mines in still on site. These can range from common items like cans and nails to countless types of pipe, steel plates, and other parts of old mining equipment.

Campsites and even towns were often built right on top of the richest mine workings, and very often over time entire camps or small towns were actually mined themselves, putting all that man made material into the mine tailings. Wherever the richest workings and most vigorous mining were are now areas rife with manmade metals.

The amounts of undesired trash targets usually overwhelms any prospector using a powerful pulse induction metal detector, and so less powerful VLF detectors are often employed in these locations to deal with the trash. This, in turn, means many deeper gold nuggets are being missed due to an inability to deal with the large volumes of trash targets. A great deal of gold remains to be found in these locations by more powerful metal detectors with better discrimination capabilities, like those described in these new patents.

I strongly believe the next few years will see significant breakthroughs in metal detector technology that will continue to aid prospectors determined to find the gold and other valuable minerals that remain all over the world. I hope this article alerts you to the possibilities that still exist for prospectors that stay abreast of the latest developments in metal detector technology.

© ICMJ's Prospecting and Mining Journal, CMJ Inc.