Small Mining Operations

Free / Small Mining Operations

Wyoming's Billion Dollar Nugget—The Trilogy Ends

July 2011 by David C.

We made it back to the site just as the storm hit. With sideways rain, and lightning, we hid out in the camper until it had passed. I determined that with a bad hose and muddy roads it was probably just a good time to throw on a rib-eye, have a beer and call it a day. Bob agreed, and with our bellies full we watched the sun go down on another Wyoming evening in the desert.

The next day I took off for home to grab my extra hose, and then headed into town to refill the gas cans. Then it was right back to the site. I replaced the damaged hose on the water truck and got back to the river.

Beautiful morning, pump in the water, here I go! Nope, same thing—slow pumping. Now what? Did I bend the impellers inside the pump when I pulled in those rocks? Reluctantly, and with that sinking feeling in the belly, I needed to pull the casing apart and inspect it for potential damage.

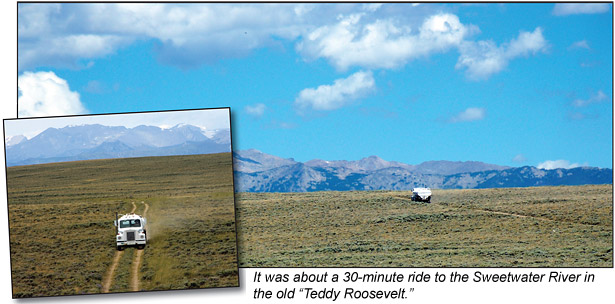

To my astonishment I found that rocks had jammed in between every impeller except one. A man can only laugh at the course of his own actions. I used a screwdriver to dig out all the rocks, and within minutes she ran again just like new. In a record time of 27 minutes I was full of water, and with the release of the air brakes old Teddy Roosevelt began its historical journey. One can only appreciate in person the sounds of a 1968 Detroit diesel that lost its internal muffler parts 30 years ago. And with the draw of all 15 gears, and the roaring of that engine, it can only make a man smile and laugh. Down the road I went; again and again; load and unload. I pondered as I drove down that historic road how many times had the pioneers hauled their ore to the river to be run, and now I was hauling the water to the ore. By the end of the day I had 28,000 gallons of water in the pits with one pond full and the second pond filling. It would only take 3 or 4 more loads and I would be ready to run. It was a good day.

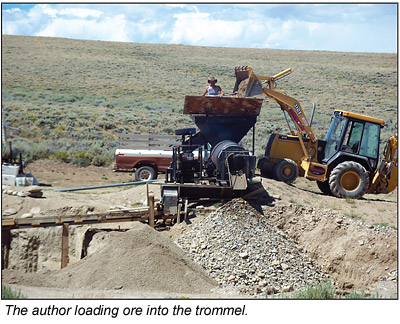

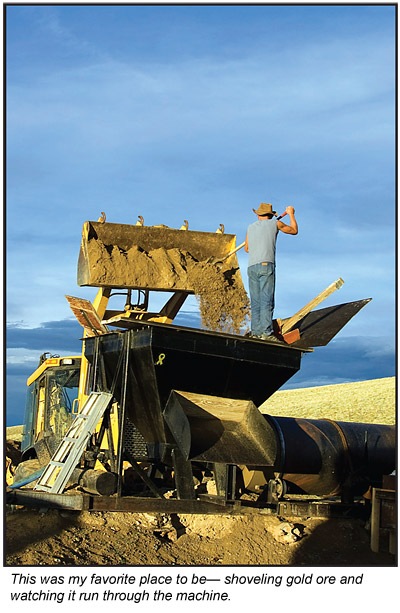

I decided the next morning to rebuild the sluice platforms and adjust the classifying equipment. Using some old reclaimed wood at no cost to me, I had the sluice system back on line by nearly lunch. All I had to do was fill the second pond up to capacity and it would be time to run. By 2pm the ponds were full, and on August 2nd the old gold mine ran again. With a turn of the key the water pump came to life, and within seconds the water flowed down the sluices along with 6 years of mouse bedding. Everything began to recirculate, so the trommel engine was started and it slowly engaged. With the clankity-clank of previous rocks, the trommel rolled back to life. I climbed onto the backhoe and got to work!

By 9pm I had run 20 tons of ore. Everything was running great and I was a very happy prospector. The old trommel was never meant for production, and only about 2 to 3 yards an hour of gravels could be shoveled into it. A hopper and grizzly with a conveyer belt was always the dream, but they cost money, and that wasn’t an option.

I was up the next morning way before dawn. All the equipment was fueled and oiled and ready for the day. With the first shadows of dawn I could see that I already had tailing sands showing at the end of the exit pipe. I guess the sandbox effect sloped the first pond more than I expected. Would I still have enough room to account for the approximate 150 tons of tailing sands? This was just one more thing to worry about. But with the morning sun cresting the eastern sky and the still quiet of the desert prevailing, it was time to make some noise.

Before lunch I had 17 loads in, and then got a flat tire. I had no way to take the tire off and it seemed to be a slow leak, so after several calls to town on my satellite phone I decided that maybe a portable air compressor was in order. Back down the mountain I went to shower off the alternating layers of bug spray and sun tan lotion at home, then get a compressor in the morning.

Another day brought another set of challenges. After refueling and a quick stop at the auto parts store, the best portable air compressor was acquired for about $70. Then it was back up to the claim again to fill the tire with air. With the tire almost full, the hose blew apart. I found out a long time ago that it doesn’t pay to get upset and instead a chuckle is always the best medicine. The tire was full enough for awhile, and Bob was coming back up that day to take some pictures. After a call to Bob the repair parts for the hose were on their way. The tire held out and I began processing ore again until Bob showed up about 6:30 that evening with the needed parts. He heard that an Aurora was to happen that night, so with a good meal, a campfire, and a bottle of tequila, we were ready for the spectacle. It never happened. The next morning I was up by 6am and heavy dew rested on all the equipment. I began with excavating the main tailing pit and then the smaller tailing pit. At 7am Bob crawled out of the back of his pickup. This was a record for the earliest that I had ever seen Bob move.

We decided that we would take one water run to the river before we started so Bob could get some pictures of the full endeavor. After breakfast and several professional photo shots, Bob needed to get back to town, and I needed to run some dirt. After running two loads of ore my friend Larry the plumber showed up and again the full tour was in order. I continued running and after an hour he said he was very impressed with the wash plant setup. He asked permission if he could go prospecting up the valley a ways and I said jestingly, “No problem. Go ahead—just bring me back all the nuggets.” Smiling, he drove away and I continued with shoveling dirt into the trommel. By the day’s end I had run 25 tons of ore from the stock pile. I decided to call the local TV news station and see if they thought there might be a story here. They decided there was, and would send out a reporter on the following Tuesday at 10am.

Friday, August 6th, included a nice sunrise. The sluices were beginning to look full of black sands with 80 tons of ore run. With the sluices full I began the messy job of cleaning the system. Gladly, I still had all the old clean-out tubs from years past, which makes the whole process a lot easier. That afternoon my old boss and his friend stopped in to see the operation. They were headed to Arizona to go find some gold. I told them, “That’s a long ways from home and we have all the gold in the world right here.” They laughed and asked if they could see some gold. I had just cleaned out the sluices that morning, but I hadn’t panned any out yet.

“How do you know your getting any gold then?” they asked.

“Because out here, there’s gold in every pan!” I answered.

I went to the nugget trap bucket and shoveled out one small garden shovel of cons into a gold pan. With the speed of a master panner I splashed out before them several thousand colors.

“How’s that?” I asked. I always love seeing that bug-eyed look in people when they think they’re seeing a lot of gold. In reality, it takes dozens and dozens of splashes to add up to anything significant. But that’s the glamour of gold.

By sundown I had run 18 more loads into the cleaned sluices and it was time to go to town to get more fuel.

After a much needed shower and spending a night at home, it was time to fuel up the gas cans and get back to the claim—time’s a wasting.

Upon arrival that morning the first sand pit was about half full and I had only taken a chunk from the biggest of the two ore piles. I figured at some point I would have to dig muddy sands to create a little more room in the pits. The trommel also sprang a leak in its wash bar pipe. I had to pull the cracked fitting back onto the pipe with some heavy gauge wire that I spun tight, then divert the excess spray water with rags and a gutter system.

That was my best “MacGyvor” because the guy that made the trommel welded the piping, so it could not be turned without cutting it all off. But I had it holding together just fine.

That day several friends had stopped by to look at the operation, and being my friends, that usually meant they had beer. I knew it was going to be a long day. I showed them all how the operation worked, but there was one who loved asking questions. I obliged his every question to the best of my ability and I think it gave him a sense of celebration because the next thing I knew he had produced a fresh bottle of whiskey. Still being friendly, I took one small shot, but it was no time for breaks. The next time I saw my liquid friend he had polished off half of that bottle mainly by himself. I grabbed the friend that brought him and said, “I think you need to take your buddy home.”

With a fierce head wind of 10 mph the old trooper fought every step he took with diligence as he struggled back to my buddy’s truck. After that group of friends left, my neighbor asked if I could turn down the rock concert. I laughed and shut off the trommel. We had a quiet beer and several laughs as I let the sluices clean themselves.

By day’s end I had still managed to run 23 loads of ore.

Sunday was day 19. I was up at 5:15am and had slept well, though my body was starting to feel the burn of age. I drove down to the river for one more load of water and then it was back up to the site to begin the run.

With eight loads processed, a pumpkin-size rock fell into the hopper, stopping the whole operation until I could lift it out. I didn’t need any more banging on the drum than necessary because the ring gear around the drum was beginning to break its weld. It was another one of those situations where you wonder how long it will last before it breaks.

It was a steady day with no company so I was able to get in 24 loads that day.

Mondays are always a tough day. It was a nice morning at 41° with no clouds and calm winds. The main sand pit was full, but I finished the biggest pile of stockpiled ore this day. With only a few loads of ore run that morning the trommel came to a sudden stop. There was that bad feeling again. After looking things over I found that one of the four mining cart wheels that the trommel sits on had locked up, and it was locked up for good. If it still spun it would be metal on metal until I finished. The only positive was that the trommel didn’t pull to this side, so I was able to lithium grease the whole ring gear so it could slip as much as possible. I only had about a hundred yards left to run and the ore pile would be finished. It was time for a prayer. With a little extra throttle on the engine the trommel spun again, only on three wheels.

A little while later that morning the nice rancher lady stopped in with an old prospector. The gleam in his eyes showed the envy that he was feeling as we stood and talked. At 83, he had prospected with many men here in the Wind River mountains and had the stories to prove it. He even knew the ol’ boy that had made my trommel. He believed that Keith, now gone, had built it around 1988. We talked for some time, and he was impressed that I was doing it all myself. He said, “That’s the way to do it.”

They stayed for a bit longer and then headed down the dusty trail. The sluices were getting full and by the end of the day it would be time to clean up again.

There was nothing quite like the smell of bacon frying at mining camp, and right after breakfast I had more company. The other rancher stopped in with his little boy. He said they acquired the mineral rights to the rest of the valley after the last mining company dropped their claims and they were wondering if it could be mined. I told him that it would be easier to make a determination after the completion of my project and we agreed to talk again at that time. They left after a little while and by 5pm I had brought the sluices up to 81 tons. It was time to clean again. In total I was up to 160 tons of ore processed so far. One more push and I should finish the mineral pile, God willing, as long as the creek didn’t rise.

My friend surprised me after returning from Minnesota that evening. She brought hamburgers, tobacco and a smile. It started off a rough day, but ended with optimism.

The next day I would be on TV. I was up with the sun the next morning and finished cleaning the sluices. I hoped that there would be thousands of dollars in those high-con buckets because I had seen some good gold cleaning out, but it’s hard to tell until you really finish running the black sands. I was going to meet the reporter in an hour at the rest area on the highway, so it was time to put on the adventure hat and look like a gold miner. The interview went very well. Once again I informed the state of Wyoming that it was sitting on a world class gold deposit based on USGS data. I showed our efforts to substantiate this data and suggested that the scientific community should further study this deposit because the historical data was over 30 years old.

It was a good day, so I loaded up the truck with the buckets of high-cons and took off for town. I took a quick shower at home and then refilled the gas tanks before heading back up to the claim.

I refilled the water truck and dug out some of the tailing sands from the first pit early that morning. The pits were close to capacity and it was a messy job. I processed another 22 tons before thunder and lightening arrived that evening. It was time to hide inside the camper again.

I was up at 6:15 on day 23, and it was a chilly 37°F. By 4pm I had processed a grand total of 200 tons of ore and my body ached. I completed another 25 loads that day.

Day 24 was the final day. It was a cold morning. I fueled all the engines, checked the oil levels, added grease to the dead wheel and got to work. After warming up the backhoe I jumped in to scoop up my first load of ore. I got a heaping bucket of gravels, just like I had done a thousand times before. Back up to the trommel I went. I lifted the bucket over the hopper, then dumped a little in. After setting the parking brake, I climbed the ladder on the trommel to the hopper platform. I shoveled in the ore, about half a wheelbarrow at a time.

I stopped after six loads to let the sluices clean for awhile. The water was so dirty that it was getting to that critical point where I could start losing gold. I continued loading ore after breakfast and had 10 loads processed by lunch. The sand pits were so full that I had to be patient. It was a nice sunny day with a slight breeze, and I decided this would be the day I would pull the plug on this adventure. At 7pm, with the sand pits full, I shut down all the engines for the very last time. I praised God in heaven that this was finally over, and I felt blessed that my equipment held out to the end. Only a tear and a moment of silence was left.

I ran 23 tons of ore the last day for a total of 230 for the season. My body hurt, but I was very content. I still had to bust everything down and haul it all home, which would take a few more days. The trommel remained in the desert for awhile until it could find a home at a new project. With nearly everything gone except the backhoe, I began to reclaim the site. I pushed the tailing pile of processed sands back into the pits and left the rest to be bulldozed the following summer. The only thing left to do was remove the engine from the trommel and set it in my truck. This was a two man job so I called my brother for help. He hooked up the chain and I lifted the engine off, lowering it into my truck.

The engine appeared to be sitting flat, so my brother unchained it. Then I saw a look of distress on his face as he flailed his arms and hopped around on one foot. I guess the engine had been sitting up on the wheel well about an inch and it came down the rest of the way right on his big toe. I knew it hurt, but I had to laugh. It was the one time this season he came out to the site and he nearly amputated his toe. I told him that it was probably bad mojo for not helping me this season, and if he wanted a souvenir I would have suggested something else. He didn’t appreciate my sense of humor.

He drove the truck out to the main road while I followed in the backhoe, and the backhoe was returned to the rental outfit.

On the final trip to the mining site that day I inspected the trommel. The constant grinding on the wheel of the trommel had left a flat spot about an inch deep on the wheel. The ring gear had one more weld to break and it would have flipped up and jammed the machine for sure. The water pipe fell apart when I removed a piece of wire that held it in place. I definitely got my money’s worth out of that equipment!

I left the site for the last time that season. We ran about 3.1 million pounds of ore or about 46,000 five-gallon buckets during three phases of operations over the past 15 years. I had accumulated 25 buckets of concentrated ore over the season, and I also had 15 buckets left over from 2004 that sat on my dad’s porch. Forty buckets was going to take some time to run.

The motor unit on the gold screw needed to be replaced. After many phone calls across America and a trip to the local auto parts store, I learned that I needed a windshield wiper motor out of a 1978 Volkswagon Dasher. Immediately one was ordered and shipped from Georgia. Within a few days I had it in my hand, and then I realized that I needed a new drive shaft, too. I’ve always been kind of pack rat. I found some half-inch round stock to accept the pulley that also had a inside diameter suitable for the motor shaft. After a bit of drilling and a new set screw it worked like a charm. It was time to run some black sand and see some gold!

I set up the finish operation in my heated shop and cut a hole in the wall for a drainage pipe. I brought every bucket I had inside to warm up, and for the next two months I ran the black sand concentrates. Each bucket was soaked with water prior to classification to 1/4-inch. I hand-fed the concentrates into the feeder, and each bucket took about an hour or so. I continued processing the concentrates after work and on the weekends as time permitted. This involved two steps.

First, I ran 12 buckets producing what I would call super concentrates. Each group of twelve buckets was reduced to about 3/4 of a bucket of super concentrates. Then I reset the angle of the Gold Screw for the last run. With the screw capturing a minimal amount of black sands, the super concentrates were further reduced to about 3 pounds. At this point, I dried out the concentrates and removed all the magnetics from the remaining material, reducing the concentrates to about 2 pounds. I panned the remaining material about one teaspoon at a time to get a capture rate of about 98%. The remaining troublesome colors of gold were captured with mercury at the end of each batch. It was nice to be still mining in a way, but without the wind and weather that the desert offers.

After 50 hours or more, the last bucket was finally processed and all of the extreme black sands were panned. It was time to weigh out the gold.

After 1997 and the first phase of operation was over it was apparent that this was a low grade deposit. But what was considered low grade in 1997 when gold was at record low levels would be considered differently in 2011 when gold prices are at record highs. And where will it stop? At $2,000 an ounce or maybe even higher? With every cell phone and computer in the world needing a pinch of gold to work. I believe it can, and will, always go up. Gold is the future, and at some point in time every significant deposit will be claimed because of its enormous value.

Our values suggest that with every 82 yards of gold ore, $1,000 could be obtained on average. Realistically, a much larger wash plant should produce thousands of dollars of gold a day. But with our test plant only producing an average of 24 yards a day, this only works out to be about $300 per day at $1,500 per ounce. This was only a test and not a continuous operation—not a bad figure for one man. Food, fuel and equipment also must be subtracted from this number along with the cost of labor. But this test wasn’t about profit, it was about results. After processing all of the stockpiled ore from the one half acre test site, 1,579 yards were accounted for. With a thickness of two feet and a area of 104’ x 208’, 1,602 yards was our target number.

This number was only missed by 23 yards, which could account for what was left in the corner of the ore pile and spillage from the heaping scoops that were taken with the backhoe.

To be continued next issue...

© ICMJ's Prospecting and Mining Journal, CMJ Inc.